Will 5 modular platform systems replace all existing multilayers?

Granulator manufacturers become active.

Thomas Reiner | 09.04.2019

Design for recycling is the central component of a circular economy. Especially in the field of flexible packaging, however, diverse and far-reaching preparations are required.

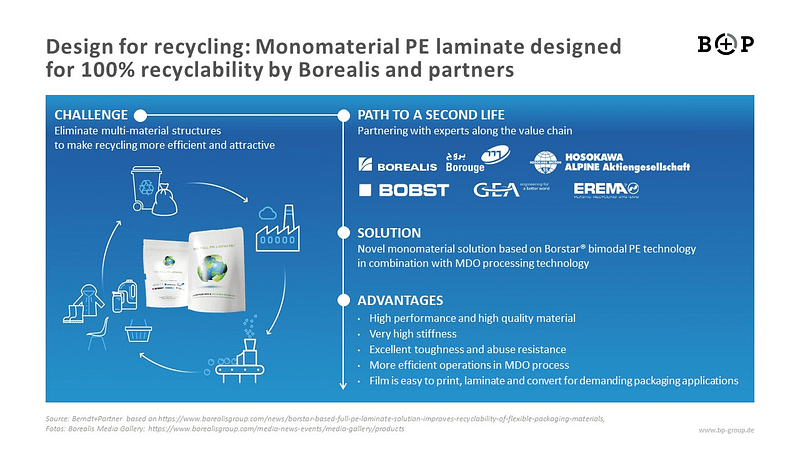

A value chain consortium comprising BOREALIS, EREMA, GEA, BOBST and HOSOKAWA ALPINE has now developed and launched the first PE monomaterial laminate. It has been developed consistently with regard to achieving 100% recyclability.

The far-reaching vision behind it: With just 5 standardized, modular platform systems, the entire multitude of currently existing multilayers is to be replaced. Intelligent marker technology is used for the simple and efficient separation of monomaterials in the sorting system of waste disposal companies.

The example shows how profound the changes in the circular economy and consistent design for recycling will be. Development will present us with major technological challenges that can only be tackled through collaboration within our value chains.

It’s clear that the material landscape will change fundamentally – and the effects will be most pronounced in the area of flexibility.